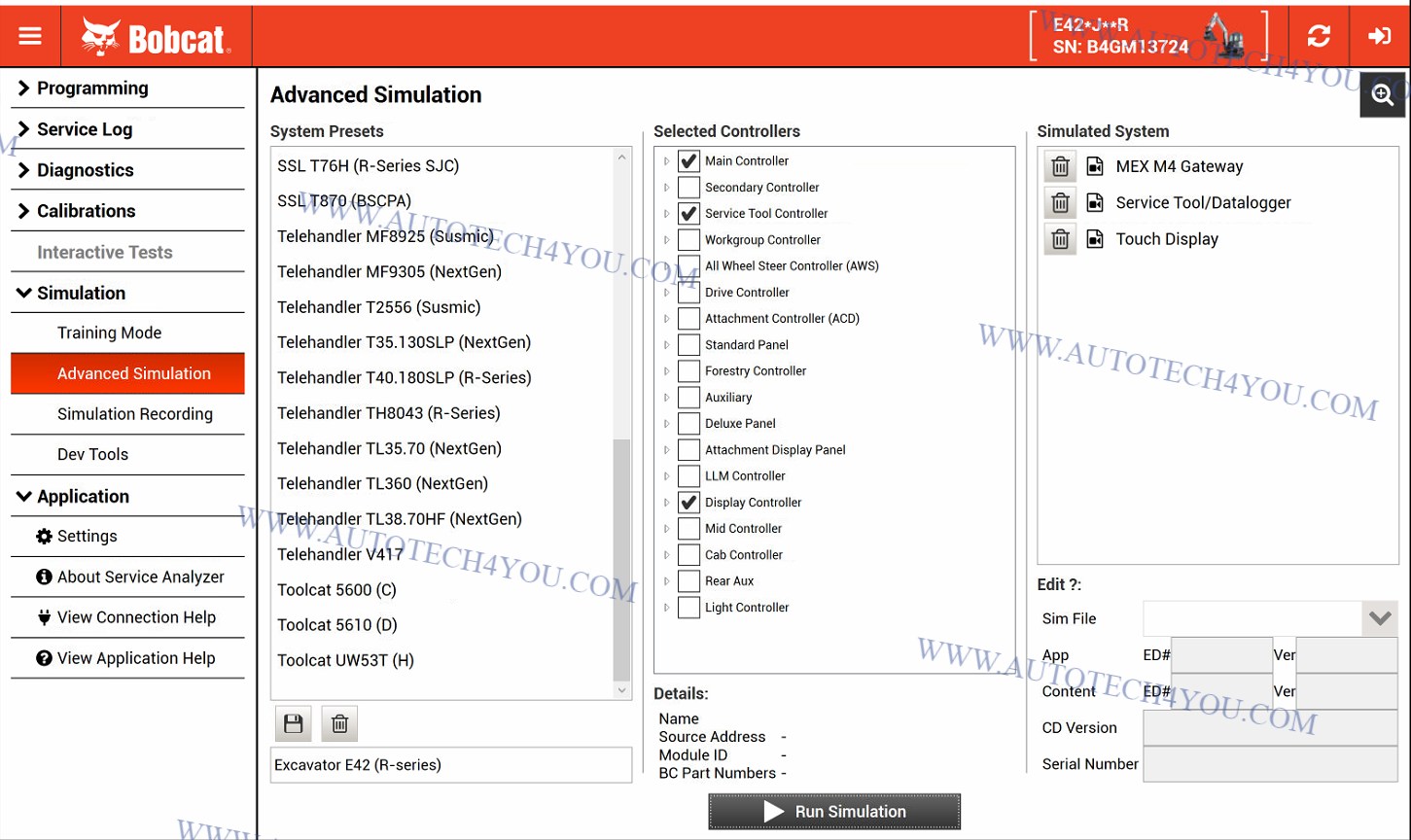

Bobcat Service Analyzer Diagnostic 91.01 01.2023

The Bobcat Service Analyzer tool comprises of programming and diagnostic tools for the Bobcat system.Bobcat Service Analyzer Diagnostic Remote Installation enables users to detect any equipment issues and fix them quickly using the diagnostic tool to avoid potential hazards. This program offers various technical information and features to help users become familiar with diagnosing their equipment correctly and preventing untimely failures.

Bobcat Service Analyzer Diagnostic Remote Installation:

- Bobcat Service Analyzer Functions:

- Software updates

- Change SN/Options

- Clear Controller Data.

- Drive pump calibration status

- Panel

- Remote Control

- System

- Vitals

- Edit diagnostic screens

- Interactive tests and etc.

- Bobcat Service Analyzer Support Models:

- CWLL85

- Excavator 331

- Excavator D19(MXGateway)

- Excavator E26(MXGateway)

- Excavator E35(MXGateway)

- Excavator E50

- SAL L28

- SSL A300(Bob)

- SSL A770

- SSL S150(Bob)

- SSL S62H(R-series Manual)

- SSL S850

- SSL T550(ACS)

- SSL T595H(Bobcat Engine)

- SSL T76H(R-Series SJC)

- SSL T870(BSCPA)

- Telehandler MF8925(Susmic)

- Telehandler MF9305(NextGen)

- Telehandler T2556(Susmic)

- Telehandler T35.130SLP(NextGen)

- Telehandler T40.180SLP(R-Series)

- Telehandler TH8043(R-Series) Telehandler TL35.70(NextGen)

- Telehandler TL360(NextGen)

- Telehandler TL38.70HF(NextGen)

- Telehandler V417

- Toolcat 5600(C)

- Toolcat 5610

- etc

Bobcat Service Analyzer Update Release Note:

Service Analyzer V90.00 – 13 Jan 2022

1. Fix to Compact Wheel Loader attachment interface not functioning correctly.

Service Analyzer V89.12 – 09 Sep 2021

- New CWL Hub/Workgroup/Drive Software (V1.2)

a. Attachment Mode Enhancements

– Increased travel speed to 20kmh/12.4mph

– Improved engine horsepower management

– Quicker Forward/Reverse transitions

– Quicker vehicle movement when using very slow speed limits - Derating and Thermal

– Increased hydraulic oil temperature derating start from 96C/204.4F to 98C/208.4F

– Increased Air Intake Temperature derating start from 48C/118.4F to 60C/140F

– Increased Air Intake Cooling Fan start point from 53C/127.4F to 55C/131F - Park brake does not need to be released to engage/release differential lock

- Power Exchange Unlock time increased from 5 seconds to 30 seconds

- Increased Aux flow at maximum paddle position

- Smoother inching pedal response in attachment mode and standard mode

- Smoother workgroup lift response

- Faster automatic park brake response on slope

- New R-Series Compact Excavator Primary Controller Software (V4.9)

a. Fixes issue with “COLD” message persisting. - Increased debounce time value to avoid No Communication faults (K42/43/4404) with TLS R-Series Road Lights and Wipers levers.

- Fix Frame Leveling wrongly enabled on the following machines:

– T35.130S: B54R11001+

– T35.140S: B54T11001+

Please get in touch with us with the below contact details for further clarification.